Magnetic Flux Leakage Pipeline Inspection Gauge

Abstract:

Pipelines, today, are used throughout the world for transportation of fluids but their inspection is a tedious task, as it involves exorbitant amounts of man-hours and money, and extensive destruction of property and materials. Pipeline Inspection Gauges (PIG’s) are an answer to this conundrum, but as of now, they are not being manufactured in Pakistan. They have to be imported from other countries, and are decidedly expensive. The objective of this project is to fabricate a PIG indigenously and thus, provide a low-cost alternative to companies importing PIGs from abroad.

Our project is to design and manufacture a low-cost smart PIG which uses the principles of Magnetic Flux Leakage to pinpoint flaws, cracks, or leaks in a pipeline. This versatile product comes in all shapes and sizes, tailor made to fit your system’s exact needs.

SALIENT FEATURES:

- Uses cutting edge sensing technology

- No external power required

- Robust

- Low Cost

- Can fit in a variety of pipe sizes

- Portable

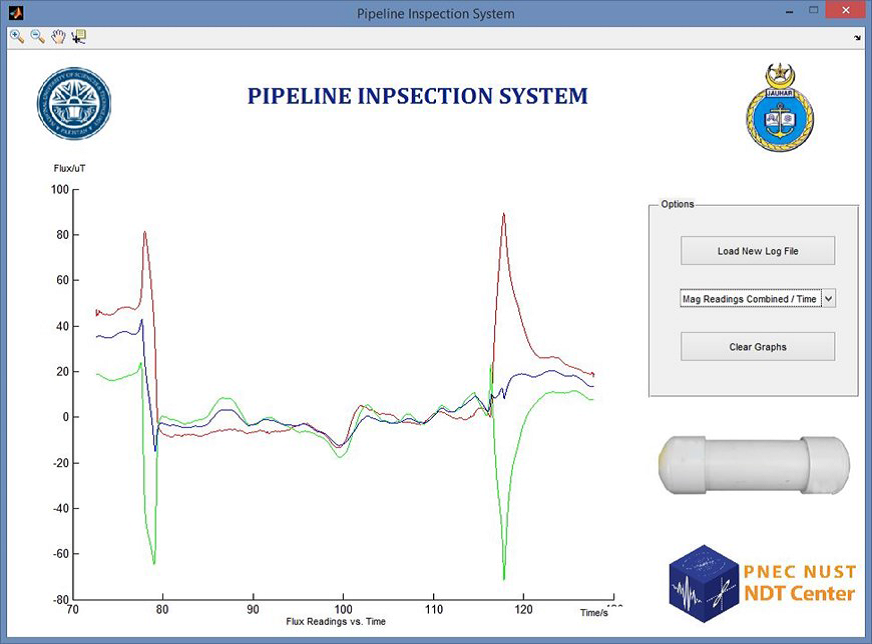

- Employs an intuitive GUI

- Indigenously Produced

- Easy to use

- Allows preventative measures that can save millions in maintenance in the long run

SYSTEM DETAILS:

The system consists of multiple subsystems. The first, a magnetization subsystem that first magnetizes the pipeline when the pipeline inspection gauge is placed inside it. The second, our specially constructed sensor array, working on the principle of magnetic flux leakage which states; when a discontinuity is experienced within a magnetized metallic structure, the magnetic flux contained inside leaks. This leakage is sensed by our sensor array and recorded on the storage subsystem. Upon the completion of the gauge’s journey through the pipeline, the stored data is extracted on to our software subsystem, which then analysis the data obtained and presents it to the user in multiple convenient and easy to understand formats, clearly showing where discontinuities such as flaws, cracks and leaks within pipelines may be occurring.

Possible Application in:

- Oil Industry

- Gas Industry

- Chemical Industry